Discover the offer

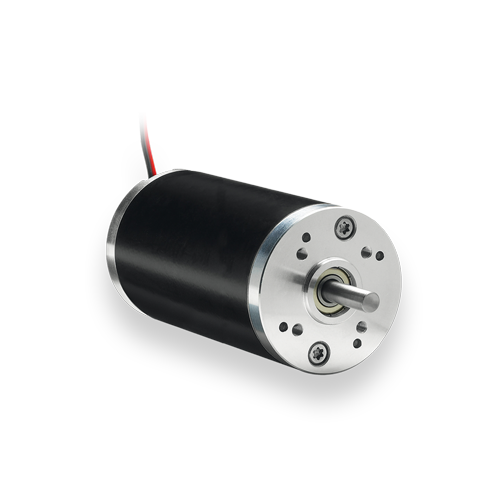

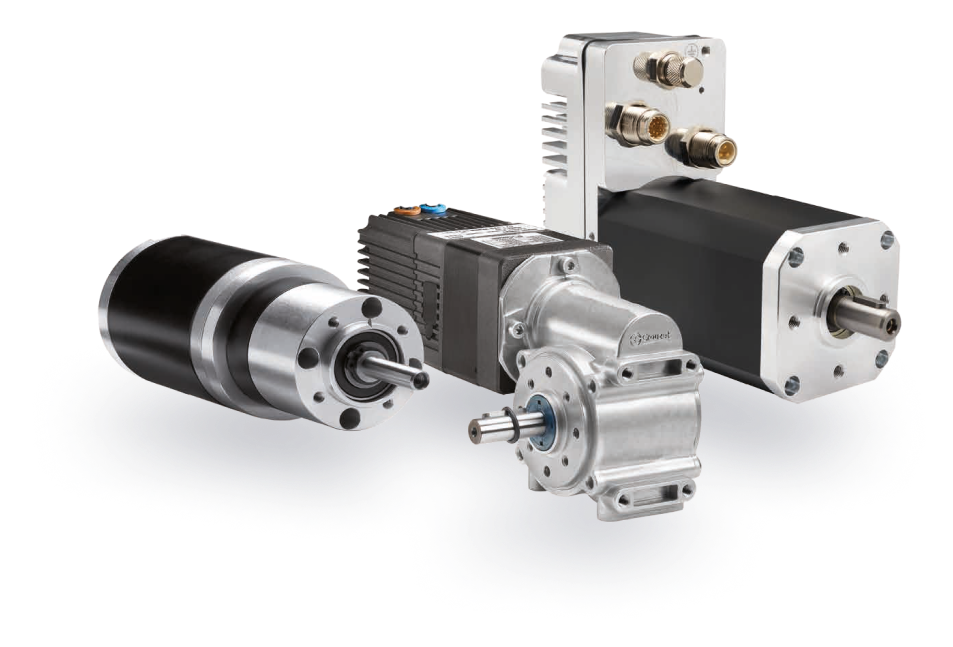

Durable, reliable and robust DC Motors.

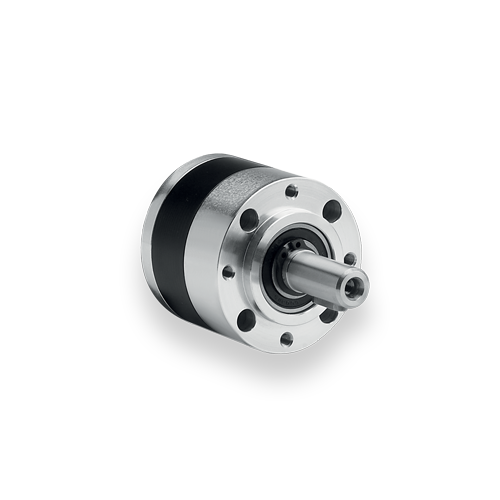

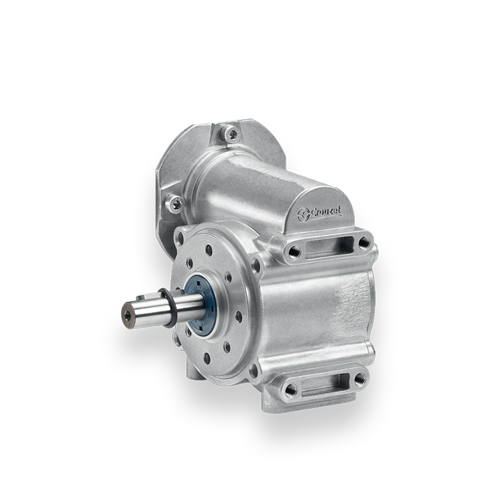

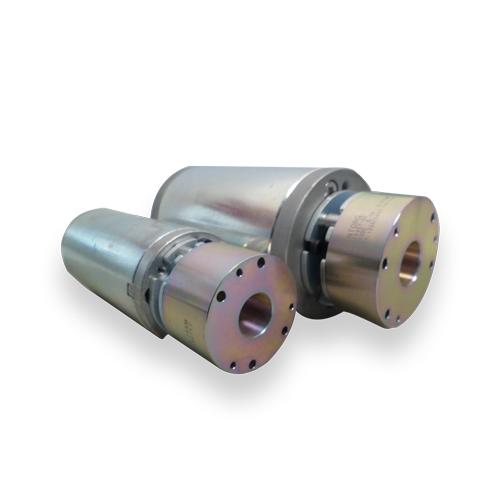

Crouzet offers a solid base of standard DC brush and brushless motors including a large number of combinations with gearboxes, brakes and encoders.

We specialize in developing taylor-made motion solutions for your most specific applications. Our 100 years’ engineering know-how allows us to provide custom mechanical characteristics, custom electronics, software adaptations, different levels of IP protection for severe environments and a wide range of international standard and certifications.

Why choose Crouzet for your motion projects?

100M+ motors delivered since 1955

Large-scale manufacturing: 2M motors per year

90% of the motors are co-designed with customers

65 years’ experience in the market

Worldwide presence

Communication protocols available on demand

Get to know the full offer

Full Product Selection Guide

If you want to choose the product that matches your specific needs, view our solutions

Driven by innovation, our experts are focused on designing and delivering the right product for the right application.

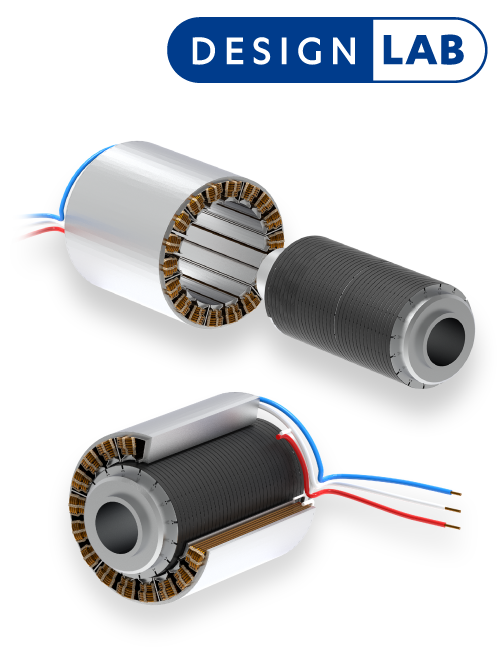

Custom motors designed

for your applications

We specialize in developing taylor-made motion solutions for your most specific applications within the shortest timeframes, offering a long-term partnership commitment and a multidisciplinary team dedicated to your projects.

Crouzet 100 years’ engineering know-how allows us to provide custom mechanical characteristics, custom electronics, software adaptations, different levels of IP protection for severe environments and a wide range of international standard and certifications.

More than 80% of the DC motors manufactured by Crouzet are adaptations from our standard ranges or 100% developed for our customers.

Adaptation example:

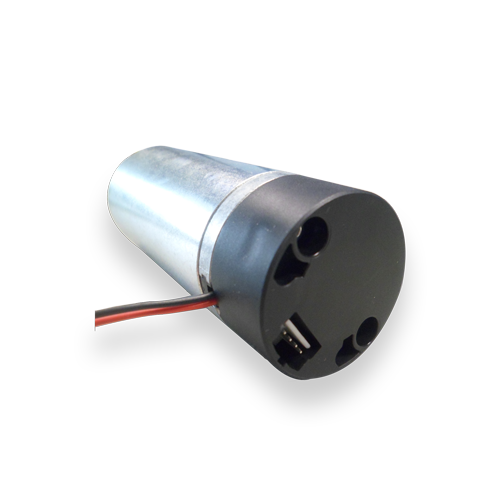

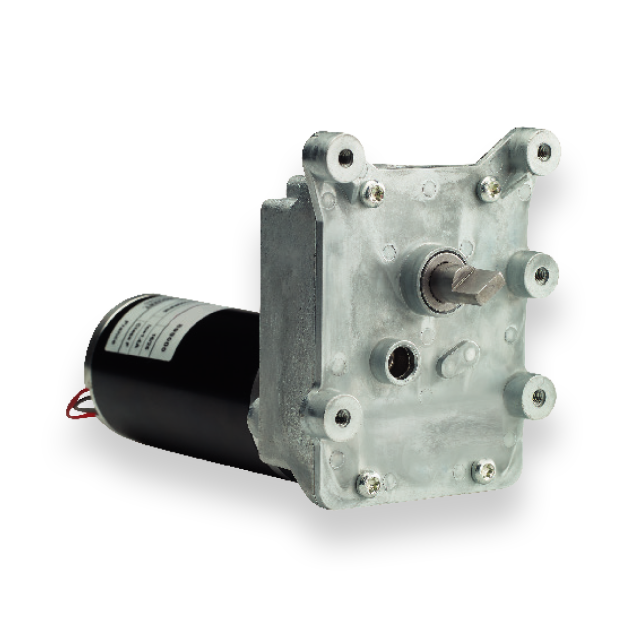

DC Brush low noise with Spur Gearbox

A medical peristaltic pumps manufacturer challenged us to co-design a cost-effective & low noise geared DC Brush motor. We came up with a solution to combine the power of silence of our DC Brush Low Noise motors in Ø42 mm with a compact and qualified spur gearbox.

Why Crouzet?

Certified for medical applications (IEC 60601-1), building automation (IEC 60950) and household appliances (IEC 60335)

Gearbox with a great efficiency rating > 82%

Wide range of reduction ratios

Super low noise level

Compact and cost-effective solution

Wide choice of options (front face mount, output shaft detail, bearing, etc)

Possibility to have a double or rear output shaft configuration