In the nuclear sector, the reliability of electrical equipment is a crucial issue. Every component used in a power plant must meet stringent requirements to ensure the safety of the facilities, even under extreme conditions. It is within this framework that the RCC-E 2012 regulation fits, an essential technical reference that defines the rules for the design, manufacture, and qualification of electrical equipment for nuclear reactors.

At Crouzet, we understand the importance of compliance with the most demanding standards. That’s why our limit switches are designed to meet the requirements of RCC-E 2012, thus ensuring optimal performance and increased reliability for critical applications in the nuclear sector.

In this article, we will explore the specifics of RCC-E 2012, its impact on the design of electrical equipment, and how Crouzet limit switches fit perfectly within this regulatory framework.

What is RCC-E 2012?

The RCC-E 2012 regulation (Design and Construction Rules for Electrical Equipment in Nuclear Facilities) is a technical code developed by AFCEN (Association Française pour les règles de conception, de construction et de surveillance en exploitation des matériels des chaudières électro-nucléaires). This code defines the requirements for the design, manufacture, installation, and maintenance of electrical equipment in French nuclear facilities.

The RCC-E provides the design and construction rules for electrical and control systems for pressurized water reactors. Developed in partnership with industrial companies, engineering firms, manufacturers, inspection bodies, and operators, it represents a compilation of best practices in compliance with IAEA requirements.

The objectives of RCC-E 2012

The RCC-E 2012 (Design and Construction Rules for Electrical Equipment in Nuclear Facilities) aims to ensure a high level of safety and reliability for electrical equipment used in nuclear power plants. Its objectives are manifold and cover several critical aspects of the operation of nuclear facilities.

Ensure nuclear safety — The primary objective of the regulation is to ensure the safety of nuclear reactors by guaranteeing that all essential electrical equipment operates reliably, even in the event of an accident. This includes:

- The continuity of reactor protection systems.

- The ability of equipment to function under extreme conditions (earthquakes, fires, floods, radiation, etc.).

- The prevention of failures that could compromise safety.

Define precise technical requirements by establishing a clear regulatory framework:

- The design of electrical equipment to meet the specific constraints of nuclear installations.

- The manufacture of electrical components according to high-quality and robustness criteria.

- The installation and commissioning of equipment, ensuring proper functioning from the outset.

Enhance the reliability of electrical equipment by imposing strict standards for:

- The quality of materials and manufacturing processes.

- The durability of equipment, particularly in terms of resistance to severe environmental conditions (temperature, humidity, radiation).

- The redundancy and diversification of electrical systems to provide backup solutions in case of failure.

Ensure the qualification and testing of equipment:

- Tests under real and accidental conditions to guarantee proper functioning.

- Validation of electrical and mechanical performance according to operational and emergency scenarios.

- Maintaining long-term performance, considering the aging of materials and components.

Strengthen maintenance and monitoring of equipment by imposing regular checks and maintenance processes:

- Maintenance and inspection procedures to follow.

- Criteria for replacing aging equipment.

- Requirements for updating and modernizing equipment based on technological developments and feedback.

Which reactors are covered by RCC-E 2012?

The RCC-E 2012 primarily addresses Pressurized Water Reactors (PWRs), which constitute the majority of the French nuclear fleet. However, its scope can extend to other types of reactors and nuclear installations. This revised code applies to existing nuclear power plants as well as the European Pressurized Reactor (EPR) of the third generation.

Crouzet Products and RCC-E 2012

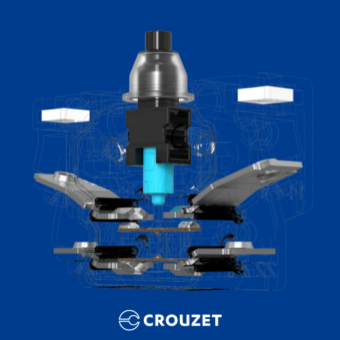

As a supplier of electronic and electromechanical components designed for harsh environments, Crouzet necessarily complies with regulations. Among their components, Crouzet limit switches meet the RCC-E 2012 code and are perfectly suited for third-generation nuclear reactors.

Solutions when failure is not an option

Enhancing safety at nuclear sites has been Crouzet’s daily mission for over 40 years. Crouzet’s microswitches, limit switches, and sensors withstand the toughest environments to switch current and detect the position of main valve shafts, motorized valve actuators, hoists, valves, generators, safety protections, and HVAC systems.

To meet the needs of the major players in the third-generation reactor market, Crouzet limit switches are also certified according to RCC-E 2012 codes with all types of categories:

- AG: Equipment required to operate during severe accidents.

- K1: Equipment required to operate under normal service conditions, during earthquakes, under normal radiation, and in accidental and post-accidental conditions.

- K2: Equipment required to operate under normal service conditions, under normal radiation, and during earthquakes.

- K3, K3AD, K3 ATEX: Equipment required to operate under normal conditions and during earthquakes.

Designed to detect positions and switch high and low currents under the most severe conditions, Crouzet switches are solutions when failure is not an option.

Limit Switches Suited to Nuclear Requirements

The limit switches offered by Crouzet comply with the RCC-E 2012 regulation. This compliance ensures that these devices meet the stringent safety and performance requirements for nuclear installations, particularly third-generation reactors.

With 46 nuclear power plants already equipped worldwide and over 100,000 high-precision, sealed, and robust switches used to detect the position (open or closed state) of safety, control, or steam valves, there is no doubt that Crouzet will continue to develop its expertise in this field to meet future requirements.

All Crouzet Limit Switches Families

Discover more

All news

AC or DC Driver? Which Choice for Automatic Barriers?

In the field of railway safety, automatic barriers at level crossings play a crucial role in…

AC vs DC Motors: Understanding the Differences to Choose the Right Motor

In the world of electromechanics, electric motors play a crucial role in converting electrical energy into…

Weight on wheels proximity switches

Weight on wheels (WoW) switches indicate whether the weight of an aircraft is resting on its…

How does a microswitch work?

Microswitches, often underappreciated yet essential, play a crucial role in numerous industrial and domestic applications. Thanks…