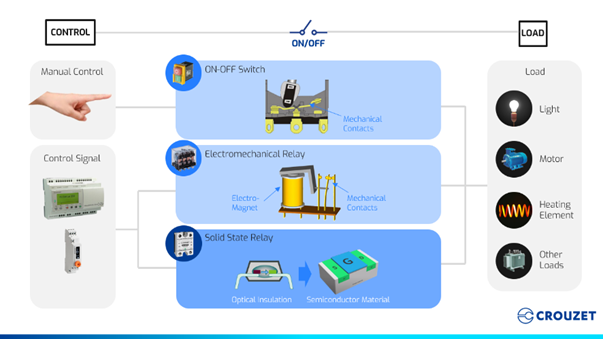

In the modern world of automation and energy management, the choice between a solid-state relay (SSR) and an electromechanical relay (EMR) is crucial for ensuring the efficiency and reliability of systems. Relays play an essential role in controlling electrical circuits, enabling the precise and safe switching of loads. However, the underlying technologies of these two types of relays differ significantly, influencing their performance, lifespan, and adaptability to various applications. This article explores the distinctive characteristics of SSRs and EMRs, highlighting the advantages of solid-state relays, which often prove to be the optimal choice for current automation needs.

Differences Between SSR and EMR

Solid-state relays (SSRs) and electromechanical relays (EMRs) differ primarily in their underlying technology, which influences their characteristics and applications. Here are the main differences between the two:

Mode of Operation

An electromechanical relay can only switch a load in an asynchronous mode: the switching of the output contact is controlled solely by the control signal, without any specific timing relationship to the power signal. In a solid-state relay, the switching can be synchronized with the output signal.

Lifespan

Solid-state relays (SSRs) generally have a longer lifespan than electromechanical relays (EMRs). This is primarily due to the absence of moving parts in SSRs, which eliminates mechanical wear issues. In fact, under normal operating conditions, an SSR can have a lifespan up to 200 times longer than that of an EMR.

Switching Speed

Solid-state relays (SSRs) have the fastest switching speed compared to electromechanical relays (EMRs). Here’s why:

- Switching Technology: SSRs use semiconductors to switch circuits, allowing for very short response times, often in microseconds. This speed is due to the absence of moving parts, enabling nearly instantaneous switching.

- Comparison with EMRs: EMRs, on the other hand, use mechanical parts to perform switching. The physical movement of contacts involves mechanical inertia, which slows down the switching process, typically to times on the order of milliseconds.

Thus, SSRs are preferred in applications requiring fast and frequent switching.

How to Choose Between SSR and EMR?

The choice between a solid-state relay (SSR) and an electromechanical relay (EMR) for an industrial application depends on several factors, including the specific requirements of the application, the operating environment, and budget constraints. Here are some considerations to help you make an informed decision:

- Lifespan and Reliability: If lifespan and reliability are priorities, SSRs are often preferable due to the absence of moving parts, which reduces the risk of mechanical failure.

- Switching Speed: For applications requiring fast and frequent switching, SSRs are more suitable due to their very short response times.

- Operating Environment: In environments with high temperatures or high levels of electromagnetic interference (EMI), EMRs can be more robust and reliable.

- Galvanic Isolation: If complete galvanic isolation is necessary to protect sensitive circuits, EMRs are generally the better choice.

- Cost: EMRs typically have a lower initial cost, which can be a deciding factor for budget-constrained applications.

- Noise and Vibrations: SSRs operate silently, which can be an advantage in certain noise-sensitive industrial environments.

In summary, for an industrial application requiring fast and reliable switching with a long lifespan, an SSR would likely be the best choice. However, if the application requires complete galvanic isolation or operates under harsh environmental conditions, an EMR might be more appropriate.

A wide range of SSRs

Discover more

All news

AC or DC Driver? Which Choice for Automatic Barriers?

In the field of railway safety, automatic barriers at level crossings play a crucial role in…

AC vs DC Motors: Understanding the Differences to Choose the Right Motor

In the world of electromechanics, electric motors play a crucial role in converting electrical energy into…

RCC-E 2012 and Crouzet limit switches

In the nuclear sector, the reliability of electrical equipment is a crucial issue. Every component used…

Weight on wheels proximity switches

Weight on wheels (WoW) switches indicate whether the weight of an aircraft is resting on its…